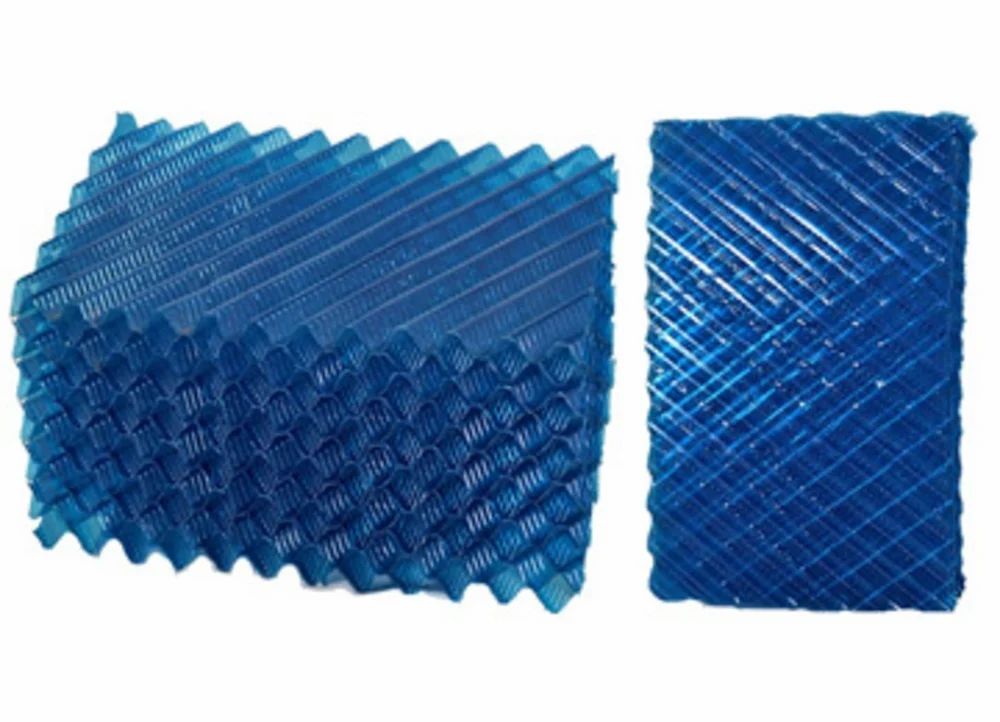

Cooling Tower Fills

Cooling Tower Fills Specification

- Material

- Polyvinyl Chloride (PVC)

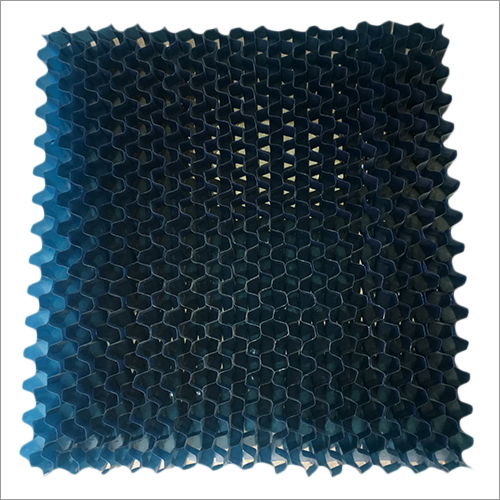

- Type

- Honeycomb Fills

- Thickness

- 0.25 to 0.35 mm

- Application

- Industrial Cooling Towers

- Hardness

- Rigid

- Surface Treatment

- Smooth Finish

- Feature

- High Efficiency Heat Transfer, Resistant to UV & Chemicals

- Shape

- Rectangular

- Length

- 1200 mm

- Flow Direction

- Vertical Cross-flow

- Width

- 600 mm

- Service Life

- 8-10 years

- Color

- Blue

- Packing Density

- 115 kg/m³

- Installation

- Easy to install, modular

- Temperature Range

- Up to 60°C

Cooling Tower Fills Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- As per product Days

- Sample Available

- Yes

- Packaging Details

- Standard

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Cooling Tower Fills

We have established ourselves as the leading manufacturer and supplier in this domain, engaged in offering supreme quality Cooling Tower Fills. They are manufactured using high grade materials. These are apt where leak proof sealing is essential because of the hazardous// toxic/volatile property of the fluid. In addition, these Cooling Tower Fills are available with us at marginal prices.

Features:

- Easy installation

- Light in weight

- Long service life

High-Efficiency Heat Transfer

Our honeycomb cooling tower fills are manufactured from rigid PVC with a sleek, smooth finish, ensuring optimal water distribution and enhanced heat transfer rates. The vertical cross-flow design supports efficient cooling for industrial towers, maximizing performance while operating within a temperature range up to 60C. This allows industries to achieve reliable and sustained cooling processes.

Durable and Long-Lasting Construction

With a service life of 8-10 years, these cooling tower fills offer remarkable durability thanks to their UV and chemical resistance. The 0.25 to 0.35 mm thickness and packing density of 115 kg/m provide structural strength for demanding industrial conditions, ensuring minimal maintenance and dependable operation.

Simple Installation and Modular Design

Engineered for convenience, these fills feature a modular structure, making installation quick and straightforward. Their standardized dimensions, at 600 mm by 1200 mm, enable easy retrofit and expansion in existing or new cooling towers. This design helps reduce downtime and installation complexity for service providers and plant operators across India.

FAQs of Cooling Tower Fills:

Q: How are these cooling tower fills installed in industrial systems?

A: These cooling tower fills are designed with a modular structure, allowing for easy and efficient installation. Typically, they can be inserted or stacked within the cooling tower frame by connecting the modules, ensuring seamless assembly and saving time on site.Q: What makes your honeycomb cooling tower fills suitable for industrial applications?

A: Our honeycomb fills are crafted from high-quality PVC, providing high rigidity and resistance to both UV rays and industrial chemicals. This, along with their efficient heat transfer capability and durability, makes them well suited for heavy-duty industrial cooling tower operations.Q: When is it recommended to replace the cooling tower fills?

A: It is advisable to consider replacement after 8-10 years of service life or if there are visible signs of clogging, reduced performance, or physical deterioration due to prolonged exposure to extreme environments or contaminated water.Q: Where can these cooling tower fills be used?

A: These fills are ideal for use in industrial cooling towers, particularly in facilities that require efficient water cooling under varying conditions. Their material and construction make them well suited to factories, power plants, chemical processing units, and similar industrial settings across India.Q: What is the process for maintaining cooling tower fills to extend their lifespan?

A: Regular inspection and cleaning are essential for longevity. Periodically remove debris, scale, or algae buildup on the fill surfaces using appropriate cleaning agents compatible with PVC. Scheduled maintenance helps maintain optimal efficiency and extends the service life of the fills.Q: How do these fills enhance heat transfer efficiency in cooling towers?

A: The honeycomb structure, combined with a smooth PVC surface and vertical cross-flow design, increases water contact area and airflow, maximizing cooling efficiency by facilitating rapid heat exchange and effective water distribution.Q: What are the main benefits of using your modular PVC cooling tower fills?

A: Key advantages include high efficiency in heat transfer, robust resistance to UV exposure and chemicals, a long operational lifespan, ease of installation, and reduced downtime. Their modular format also supports flexible system upgrades and maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Fills Category

Pvc Drift Eliminator

Hardness : Rigid

Type : Drift Eliminator

Thickness : 1.2 mm

Application : Cooling Towers, Air Handling Units

Pvc Cooling Tower Fills

Hardness : Rigid

Type : Cooling Tower Fill

Thickness : 0.25 0.30 mm

Application : Water Cooling Towers

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS