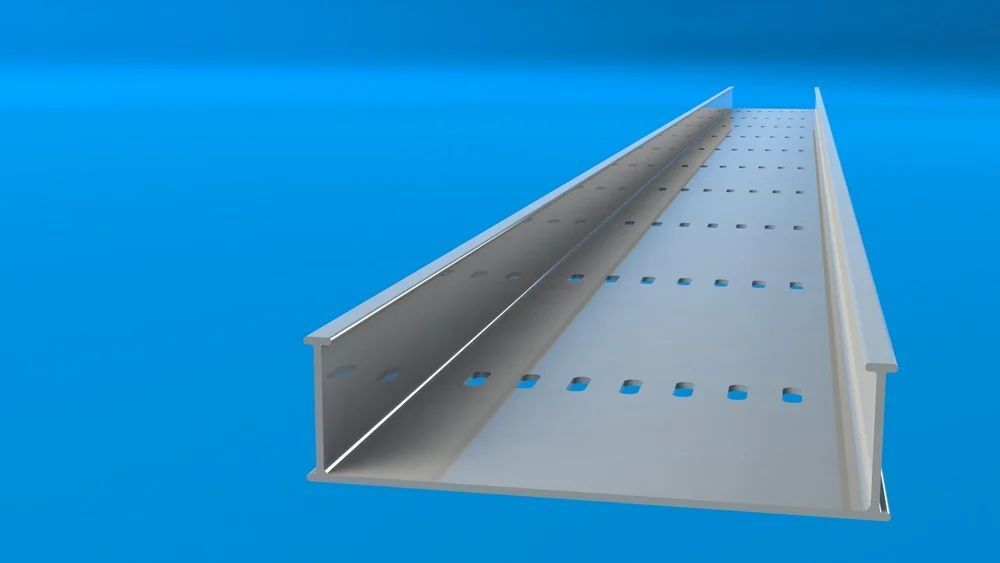

Industrial FRP Trays

Industrial FRP Trays Specification

- Surface Finish

- Powder Coated

- Product Type

- FRP Trays

- Usage & Applications

- FRP trays are used in pharmaceutical and food processing industries for handling and storing products.

- Color

- Colorless

- Features

- Durable

- Frequency

- Milihertz

- Material

- FRP

- Rated Current

- Megaampere ( MA)

Industrial FRP Trays Trade Information

- Minimum Order Quantity

- 1000 Feet

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Foot Per Day

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Industrial FRP Trays

Industrial FRP Trays

We are a profound manufacturer and supplier of an excellent grade collection of Industrial FRP Trays. The provided trays are manufactured using quality approved fiber-reinforced polymer with the aid of latest techniques under the direction of our diligent experts. Preventing entanglement, abrasion and other related damage risks, these trays are known to provide ease in supporting cables and wires. In addition, the offered Industrial FRP Trays can be availed from us at market leading price.

Industrial FRP (Fiberglass Reinforced Plastic) trays are specialized containers or vessels designed for various industrial applications. They are made from high-quality FRP materials, offering excellent durability, corrosion resistance, and strength.

Key Features

Corrosion Resistance: FRP trays are resistant to corrosion from chemicals, acids, and other harsh substances.

High Strength-to-Weight Ratio: FRP material provides a high strength-to-weight ratio, making the trays durable and lightweight.

Chemical Resistance: FRP trays are resistant to a wide range of chemicals, making them suitable for use in various industrial applications.

Easy Maintenance: FRP trays are easy to clean and maintain, reducing downtime and increasing productivity.

Applications

Chemical Processing: FRP trays are used in chemical processing industries for handling and storing chemicals.

Industrial Manufacturing: They are used in various industrial manufacturing processes, such as parts cleaning, degreasing, and surface treatment.

Pharmaceutical and Food Processing: FRP trays are used in pharmaceutical and food processing industries for handling and storing products.

Waste Management: FRP trays are used in waste management applications for collecting and storing hazardous waste.

Benefits

Long Service Life: FRP trays have a long service life due to their resistance to corrosion and durability.

Reduced Maintenance Costs: FRP trays require less maintenance compared to traditional materials, reducing costs and downtime.

Improved Safety: FRP trays are designed to handle hazardous materials safely, reducing the risk of accidents and injuries.

Considerations

Material Selection: The selection of FRP material should be based on the specific application requirements, including chemical resistance and temperature tolerance.

Design and Fabrication: FRP trays should be designed and fabricated according to industry standards and regulations.

Quality Control: Quality control measures should be implemented to ensure the trays meet the required specifications and standards

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Trays Category

FRP Cable Tray

Price 150 INR / Meter

Minimum Order Quantity : 100

Material : nil

Usage & Applications : as for costmer

Standard Thickness : 10 Meter

Warranty : no

Lock Spacer

Price 150 INR / Pair

Minimum Order Quantity : 100 Pairs

Material : nil

Usage & Applications : as for costmer

Standard Thickness : 10 Meter

Warranty : no

Splash Cap

Price 10 INR / Piece

Minimum Order Quantity : 100 Paints

Material : nil

Usage & Applications : as for costmer

Standard Thickness : 10 Meter

Warranty : no

FRP Tray

Price 150 INR / Meter

Minimum Order Quantity : 100

Material : nil

Usage & Applications : as for costmer

Standard Thickness : 10 Meter

Warranty : no

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS